Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your craft with precision that commands attention!

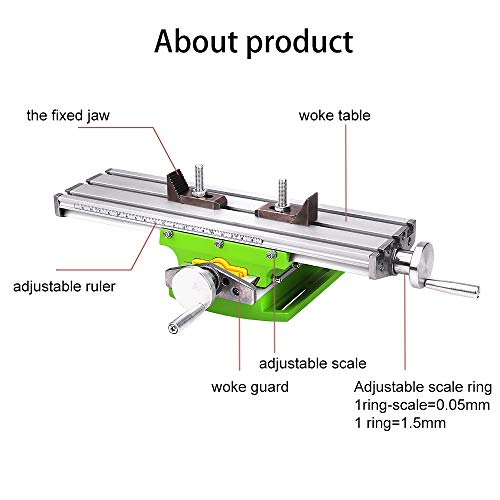

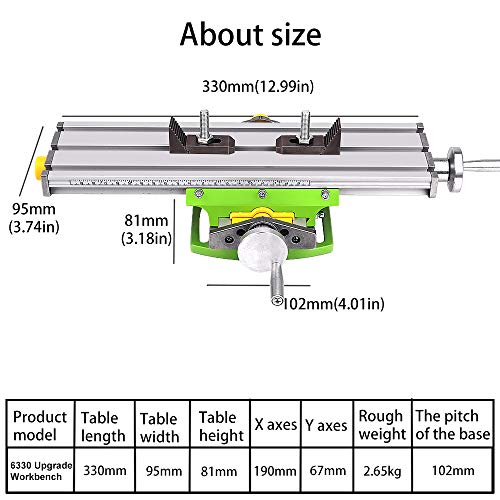

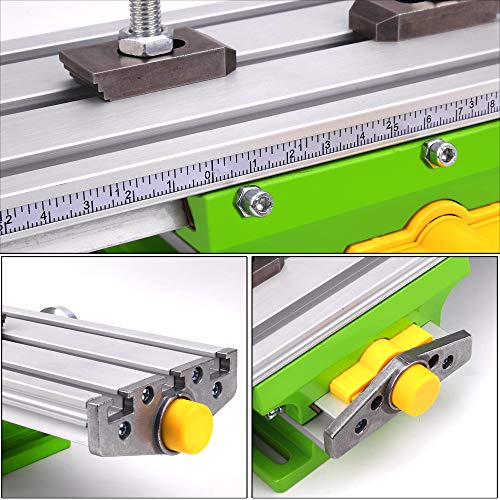

The MYSWEETY Compound Slide Table 6330 is a compact, multifunctional milling worktable designed for mini drills and compatible machines. Featuring a durable carbide steel and aluminum alloy construction, it offers precise X (190mm) and Y (65mm) axis adjustments with a finely graduated hand wheel scale. Its 330×95mm surface and dovetail slot design ensure accuracy and space efficiency, making it an ideal upgrade for hobbyists and professionals seeking enhanced milling control.

| ASIN | B07GXH3HWZ |

| Assembly Instructions Description | A manual containing assembly instructions is included with the product. |

| Assembly Required | Yes |

| Assembly Type | Require Assembly |

| Base Type | Leg |

| Brand | MYSWEETY |

| Capacity | Medium |

| Color | Green |

| Colour | Green |

| Country of Origin | USA |

| Customer Reviews | 3.9 3.9 out of 5 stars (146) |

| Date First Available | 7 December 2018 |

| Item Model Number | 202436-US2 |

| Item Part Number | 202436-US2 |

| Item Weight | 2 kg 610 g |

| Load Capacity | 1E+2 kg (220 lbs) |

| Manufacturer | MYSWEETY |

| Material | Aluminium |

| Minimum Height | 95 Millimetres |

| Net Quantity | 1 Count |

| Primary material | Aluminium |

| Shipping Weight | 2.61 Kilograms |

| UPC | 700961985841 |

| What is in the box? | Cross Table |

S**D

Not that good for what I aspect it

M**D

I bought the $60.00 unit which I believe is made completely different than the $30.00 model which I think is confusing people into thinking they are all junk..Let me start by saying the larger model I bought is not real far away from the "kinda junkyish" label but I would not label it as "junk because it's only $60.00,I paid $80.00 for my 29mm Snap On combination wrench and that was 20 years ago so I'm a pretty good judge of amount of money spent versus usefulness and also that it makes something possible that would have otherwise been impossible without it..Time is money and It immediately paid for itself on my first project as I've been doing things freehand lately and you really just can't make perfectly straight and consistent line by hand (or at least I can't) The biggest flaw is the incredible amount of free play in the y axis but if you just remember it's a minor inconvenience and allow for it the problem is solved,I read about the slop so I was already prepared to deal with it. I also wanted to mount mine on a Dremel work station and it does fit on the base of the Dremel but it didn't leave much room underneath so I am mounting the table back to back directly behind the Dremel work station,the Dremel head spins 360° on the pipe its attached to so it's a simple matter of rotating the head 180° to the table.The two tools butt up together as the picture I included shows so you may have to mount your work to compensate for a small loss of the y axis or I believe if you mount it at an angle to the Dremel it sit further towards the center of the cutter..I will mostly use mine for project boxes and light hobby work and realize the difference between this one and one's that are the same size but weigh 60 pounds.. I know no professional machinist would buy one of these because they wouldn't be caught dead with one of these but it seems they are being used way beyond their capacity and likely have never been tightened up and adjusted which isn't the tools fault..

J**C

Didn’t work for us

K**W

After some gib adjustments, the table was fairly solid. It came with screws and clamps that worked fine for mounting my vise and holding a plate for drilling. The X axis screw is like a Bridgeport (turn it clockwise and the table goes left) but the Y axis is opposite, when you turn it clockwise and the table comes out. I have it mounted on a small drill press but never expected to turn it into a milling machine. I did try using an end mill but as expected, it didn't work. My only complaint is the dials on each axis can rotate so you can set them at zero but when I move the table they slip and zero is lost. The table does perform well except for the dials so 4 stars and I hope to find a way to tighten them. Edit: I've attached a picture of a 6-32 set screw I put in to hold the dials in place. Dials are easy to remove, made of aluminum so they are easy to drill and tap. Don't over tighten the set screw and this fix should last a long time.

M**C

This is a great value for money. It all works as you would expect for a product in this price range. It is a reasonably well engineered product. It does however have tolerance issues and would not be suitable for metal routing. This is good for lighter work but even so, lacks the accuracy for precision parts. Bottom line: Value for money, great for hobbyist.

Trustpilot

2 weeks ago

3 days ago