Customer Services

Copyright © 2025 Desertcart Holdings Limited

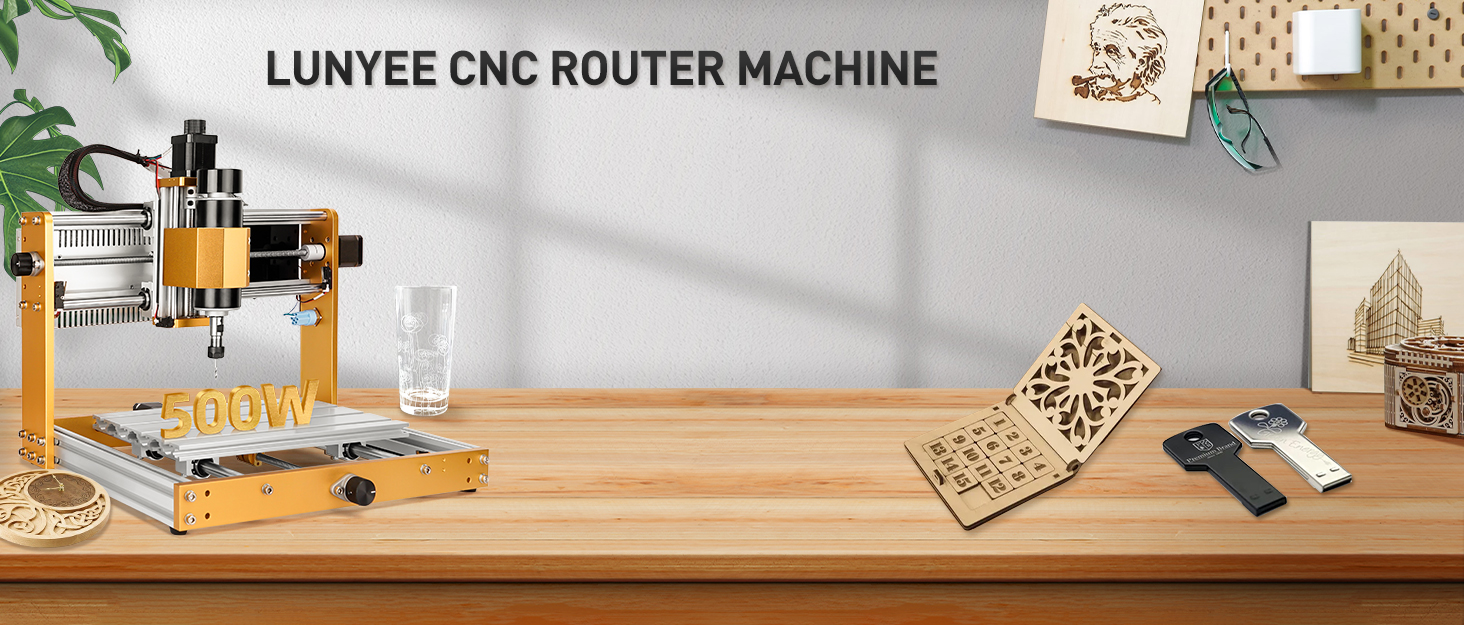

⚡️ Elevate your craft with precision power — CNC mastery in your hands!

The Lunyee 3018 Pro Ultra is a professional-grade, all-metal 3-axis CNC router featuring a powerful 500W spindle and upgraded HGH15 linear guide rails for superior precision. Designed for metal, wood, acrylic, and PCB engraving, it includes an integrated power supply, emergency stop, and limit switches for enhanced safety and control. Its machined aluminum platform with scale grid and T-track clamps ensures stable, accurate workholding. Pre-assembled components and comprehensive support make it ideal for millennial makers seeking reliable, high-performance CNC machining.

| Brand | LUNYEE |

| Material | Aluminum |

| Power Source | ac/dc |

| Voltage | 110 Volts |

| Item Weight | 14 Kilograms |

| Horsepower | 500 Watts |

| Maximum Rotational Speed | 12000 RPM |

| Base Type | Fixed |

| Battery Description | Corded electric |

| Manufacturer | LUNYEE |

| Part Number | 3018 pro ultra |

| Item Weight | 30.8 pounds |

| Package Dimensions | 20.7 x 18.2 x 11.9 inches |

| Item model number | 3018 pro ultra |

| Style | 3018 pro ultra |

| Wattage | 500 watts |

| Batteries Included? | No |

| Batteries Required? | No |

| Description Pile | Corded electric |

P**S

Great Beginning Machine to learn how to use a CNC router. Cheap/Small/Portable

Had an issue putting it together, but customer support (via email) was able to spot the problem and quickly get me going again (HINT - The e-stop harness fits in a couple of different spots on the controller board....but the machine will not work if you put it in the wrong one!) Anyway, machine seems well built. The included USB drive got the software needed to try out the machine loaded over to my laptop and I fired it up and made some test runs. From there it's been a bit of a learning curve but I'm currently working on my first self-designed project which I programmed using Easel. I think this has been a really good machine for me as my goal was to learn how to use CNC without spending a ton of money. This machine is limited in capability just because the machine is so small. BUT, the fact it is so small keeps the price down and means I can set it up on on a work bench and move it around as needed easily. Seems to be the perfect machine for me right now and in an ideal world I'll be upgrading to a larger machine in the future.

P**B

Good Table Top CNC at this Price Point

Well worth it at this price point. Very sturdy and reasonably designed for a small desktop CNC milling machine. It was fairly easy to assemble. The instructions for assembly were decent. Did have to look at the website for a few things. The printed instructions that came with it had a QR code for help that was a broken link. But, a simple Google search brought me to the Lunyee web site. The web site was simple to navigate and has lots of good stuff like info and software. The version of machine I received as shipped came with a PCB control board with one thing I didn't like. The E-Stop would make the machine stop 'eventually' but not always right away. I contacted customer support via email and got a quick response. The emails came fast and they worked quickly to resolve my concern. They sent me a new PCB and now the E-Stop works as expected with immediate stop when pressed. I have only carved wood with it so far and it seems to do a good job. I recommend getting a dust collector setup similar to what I have in the photo. The Lunyee part for dust collection that attaches to the spindle column was a separate purchase. Then of course you would need a hose and dust collection system. I went with a DIY version of a 'Dust Deputy' and a shop vac. The hoses etc. fit without clamps to the Lunyee part. You can use the 'Offline Controller' or a USB connection to a computer; but not both at the same time. You can only connect one at a time. The preferred method is a computer with the right software, but in a pinch or just to test it out, the 'offline Controller' works decent as a standalone option. Seems to have enough power for soft wood and plastic. I have not yet tried with hardwood; should be alright at slower speeds. For some soft metals like aluminum, I would only do relatively light engraving and shallow milling.

A**K

Great Little Machine - Questionable Manufacturer's Customer Service

The machine (Lunyee 3018 CNC)arrived within the promised delivery period. The box was in good condition, and, inspection showed no damage to the contents. When comparing the contents, with the list / description in the Owners Manual, I discovered the following incorrect or missing pieces of hardware*, which will prevent me from completing assembly of the machine until I receive them, or go to my local hardware store and purchase them: a) Screw M5-10 (4 pcs) - to install Control Panel -- the screws were not included. b) Pan Head Screw M4-8 (4 pcs) - to install Rubber Feet -- the screws were not included. I contacted the Manufacturer's Customer Support, but received no response from them, so, I ended up purchasing the items on my own, in order to complete the assembly and be able to use the machine. * NOTE: The manufacture did finally get back to me, apologized for the delayed response & the missing hardware. The manufacturer did replace the missing hardware, so, I am upping my rating from 3-Stars to 4-Stars. The machine went together fairly easy & quickly, due to some awesome User Created Assembly Videos (the videos made by the manufacturer were lacking). I purchased this Lunyee 3018 CNC, in order to offload some of the workload (smaller cutting & engraving pieces) from another CNC (NymoLabs 5040 CNC) that I also purchased via Amazon. The machine appears to be well built, is easy to operate (the included Candle Software is great), quieter than I thought it would be, and, to my surprise, the cuts / engravings were better than those made by the NymoLabs 5040 CNC. The only reason I gave this a 3-Star Rating has nothing to do with Amazon. It was due to the missing bolts / screws, the lack of Customer Service Response from the Manufacturer, and the lack of good Assembly & Use / Operation Videos from the manufacturer. If they (the Manufacturer's Customer Service) fails to respond on a simple issue / problem, I hate to think what would happen with a major issue / problem. Other than that, overall, this is a good little machine that I would recommend to people with some CNC experience, or to newbies who are willing to do a little work on their own - purchase minor missing hardware ( bolts / nuts / washers / screws) and scour the Internet for helpful tips, trick, videos, etc... - rather than rely on the Manufacturer.

C**R

Amazing CNC machine

I've wanted, and needed, a machine like this for several years, intending to use it to make parts for telescopes. The reviews that I read for other machines scared me off with comments about plastic parts and low powered motors. A router/milling machine needs to be very rigid and square and have a powerful enough motor for the material you intend to use. This machine meets these requirements. Very impressed with everything from packaging, to assembly, and performance. Everything you need is here, including a nice set of starter bits The packaging is very nice and very well done. All parts are easy to locate and complete, no missing parts, no damaged parts. The machine arrives in two major preassembled parts. They are easily bolted together. Total assembly could be done in 1 to 2 hours. I took my time and still had the router up and running in very little time. Wires are labled very clearly. The motor fits very snugly in the housing, be sure to loosen the bolts enough and align the motor to the holder. If the motor is the least bit tilted, it will not fit, the tolerences are very tight. The instruction manual is very helpful and is simple but complete including wiring diagrams. There are videos on the internet that show how to do the cable management easily, all need parts included. The machine looks very neat when finished. All assembly tools are included, Super Lube for the moving parts.... very nice! Assembly was easy and everything fit nicely. The bed is fantastic, just like a professional mill, it has evenly spaced drilled and tapped holes for the clamps. A graduated scale etched into the surface. Also very stable with no play. What could be better. More than I expected. Very nice. No plastic parts on this machine, all structural parts are metal. The X axis has very nice guide rails instead of metal rods. Z axis the same. No play anywhere, all moving parts very stable out of the box. Square the gantry to the bed and bolt the two together with 12 bolts. No additional adjustment required. Fit and finish of all the parts is excellent. The machine runs great. Connection to the computer was easy, using the supplied driver and Candel software. Other control software from the internet, g Sender etc. all worked well. This is a really beautiful machine. On the level of an industrial machine. Surfacing a sample piece showed very smooth tool marks, a Bridgeport mill is about the same and costs tens of thousands more. I know, I was a manufacturing engineer for several years. Amazing what can be done with stepper motors. Repeatability seems very good, much like a 3D printer (a good one). A mill is more difficult to use than a printer mainly becuase you have a very sharp rotating bit that can collide with your clamps and bed if you are not very careful. Try to air cut your parts as a test without clamps, or a bit in the router, and NO workpiece. Test the machine movements before you cut anything. Then cut foam or some soft material so you will not break a bit, or something else. Use a thin scrap piece, larger than your workpiece, on top of the bed so you will not damage the bed. Protect the bed! Chose the correct feed and speed and bit for the material you will be cutting, experience is a very good teacher. Be careful, this is a real machine not a toy. Overall, I am very impressed with this machine. Watching it run is fascinating and took me back to times long ago in industry. Now, it's here on a desktop, with the accuracy we thought impossible and using very similar g codes! The machine is designed for smaller projects, which is exactly what I need. If you need a very large bed, this is not for you. The dimensions are as advertized. If your projects fit this size machine, I think you will be very pleased. I don't see how you could do better at this price level. I'm not going to try to improve upon it, everything works and works very, very well. I will clean it, lube the screws, change the bits, program parts and enjoy the results. What more could I ask? P.S. I would very much like to order the lasers and blast some plywood!

A**G

Great hobby, easy to get started with this well built router.

I needed a hobby for the winter and this is it. I have worked around manufacturing for most of my life so I am familiar with machining but this was my first jump into something like this. My journey has just started but I wanted to share a few things that I like about this router and a few things that I learned on the way. Equipment itself - Overall it is heavier than I was expecting - very solid and well built. The components are easily replaceable for any future upgrades or maintenance needed. - The mechanical assembly was very easy. Most of the pieces are prebuilt so it is just attaching the gantry, hang the power supply and screw on the circuit board. One tip is to use a square/right angle to make sure the gantry is perfectly square to the base. - There were no wiring instructions but I went onto YouTube and there are a few videos that show it well. All total it didn't take much time at all to assemble and the wire paths look nice compared to pictures of other similar routers. - Software - There was a thumb drive that came with it but I personally could not get anything to work from it. I went online and downloaded EASEL (Drawing program) and UGS (Sends the program to the router). There is also Candle software (Sends the program to the router) that also seemed to work as well. Two things you need to know is your COM port and your version of windows (64bit vs 32bit). These are all free software, very intuitive and have good videos on YouTube to get started. - Spindle/solid z axis. I'm glad I went with this unit that already has the larger 500W spindle for the extra power. I was comparing this unit to other competitor products and this had the upgrades that you would do anyway. The z axis is solid and has plenty of travel for what I need. I'm mostly cutting 6" wide by 1/2" thick boards but you could do 2" thick material pretty easily. The cutting motion is very solid and smooth. This type of machining is not jerky like a 3D printer. - Customer service. I did have one component that needed to be replaced. I saw it online for $9 but sent an email to Lunyee and they responded the next day and had me running very quickly. Most of the components on this machine can be replaced pretty easily but it is nice to know that there is great customer service available if there is an issue I can't resolve myself. Lessons learned: - The first thing I recommend is to cut a piece of scrap plywood and attach it to the aluminum table. I used the clamps that came with it on a couple projects and the screws scratched the table (Nothing bad but I didn't want to continue it for very long). The plywood allows me to cut out shapes and can be replaced easily. - Learn the masking tape/glue method to hold your wood to the table. This is cheap and it works. No more holes and rough spots on the bed. This made everything work so much better than the clamps. - Dust control. When vacuuming the dust, be careful of the limit switches. They work well and I have set them off mistakenly when trying to clean up during a run. Having to restart a program is a mess so be careful. I don't see the need to invest in a hose attachment or side shields right away. I just use my shop vac every once in a while and that seems to work just fine for this level of work. - Find a supply of flat wood. This is probably the hardest part of the whole process. The wood in the big box stores is mostly bent so you have to be selective. I think that the masking tape/glue process to hold the material helps but a good straight board is important. - Cutting tools. This surprised me but you don't need as much here as I thought. I bought a cheap set that included endmills, ball nose mills and some vcut/engraving bits. I thought I would be breaking them all the time but they have held up well. The only one I broke was dropped on the floor. You don't need to overstock on these as long as you don't start crashing into clamps or mess with the cutting settings (I have lots of time). Pictures: I attached a few pictures to show some of my wins and learning: - Queen of Spades - I worked hard on this one and almost finished before it went bad. I was using a vcut bit to do the outer edge all the way through the wood but the bit was too short. The spindle hit the wood and broke the material free from the clamps. As you can see, it went a little crazy and cut a path right through it. This was my first project with a lot of detail and really enjoyed it. - Cow - this is one of my favorites. I pulled the picture off of a black and white clip art image. I really like how the deep images look with the carving tool. - Einstein - I wanted to try to carve a face and pulled the first black and white picture that came up. It looks great when held at different angles. - Heart sign. This was my last carving using the Easel software. The free pro license only lasts 30 days and then they charge $30/month. I really like how easy Easel was to use so it may be worth the cost. I'm going to transition to the VCarve software which is a one time fee and looks to have quite a bit of additional features for added challenges. You can do a lot with the free software but if you want to carve the fancier projects, plan to spend a little money to get the good software. - Pictures of the wood bed with clamps and tape/glue method. You don't have to worry about hitting a clamp with a spindle with the tape method and you can use the whole surface. I'm having a blast with this router and could go on and on. I'm not going to become a millionaire (Or even dollaraire) from this hobby, but it is fun to make a little projects when it is not nice enough to do much else. Good luck on your adventures.

A**N

Sadly, a lot of my and my son's money wasted.

Money spent: $450 for the CNC machine, $300 for a new laptop to run it, $60 for extra bits. All in, $810. Estimated time spent trying to get this thing to connect to multiple top software options: 30 hours. Projects completed: 0 This purchase has been one of the most disappointing, frustrating, money pit of a project I've ever embarked on. What began as an exciting idea to get my son off electronics, has turned into a life lesson on buyer beware. What upsets me the most is my son, who doesn't have a lot of money, put in $250 of his own money to get it (we picked up the rest for his birthday in the hope it might spark an interest as he is going into college next year). Instead he got a machine that has no included software (short of crude and antiquated software on a thumb drive). Instead they point you to third parties which, you guessed it, poorly integrate withe the machine. I've watched how-to videos and read countless articles (most in Chinese, but thanks to translation software I was able to read it), yet I was unsuccessful to get this thing to consistently do anything. Now I (we) have over $800 in equipment with about 30 minutes of run time on it, and nothing to show for it but frustration and disappointment. If you are considering this machine, unless you are an engineer educated in CAD, my recommendation is to look elsewhere. I would consider myself better prepared than some to tackle something like this (years of experience in woodworking, BS in a technical discipline, Masters in another, and oversee IT professionally), but I still failed to figure it out. If I had to do it over again, I would only consider CNC machines that have their own software integration/partnership.

A**N

beyond 5 star - both for customer support, price and product quality

I am very impressed with their customer support, which is above and beyond. I am a Mac user and totally new to DIY CNC machine. Struggled and need support for almost each step in the initial setup. Lunyee customer support was amazingly fast and responsive. They responded to every single questions I had, and even had a couple calls for troubleshooting. I think all DIY CNC machines are more compatible with Windows-based computer, therefore I had more issue, like the comms and driver for Mac. They provided me with different alternatives, sent me spare parts to swap, etc. They are very forward looking by incorporating all the lesson learned into a detailed User SW SetUp Instruction document, so that all the future users can benefit from it. What more can you ask?! The machine is solid, well-designed, stable, and using high quality aluminum parts. They put good attention to details in their machine and packaging, including things like cable routing, connector/cable color matching, sub-assembled parts, so that the size of the shipping package is not huge but can still protect the machine well, while the DIY assembly effort is reasonable. They continue to make the system more user friendly. The original instruction suggested to use Candle as the G-code SW, which was a bit raw and complicated for new user. After my feedback, they switched to suggest using Easel with step-by-step setup instruction. I think it is so much easier now. In summary, Lunyee is the most price competitive DIY CNC I see in Amazon, they have great machines, the sw package and instruction continue to improve, last but not the least, amazing customer support which you can rely on. (I am working on my first project, and already down to the last couple sets. Will share some pictures in this review later. excited)

N**Y

Beefy 3018 on steroids

So i have a 3018pro from 2013 it was a pretty good machine for wood and foam but, put aluminum down it loses its mind, with this new 3018 pro ultra machine its super easy to assemble threaded holes instead of those twist in and hope nuts, its super sturdy and solid and cuts aluminum, great 500 watt spindle is extremely quiet compared to 775 motor running full 16mm linear rails on the x and 13mm ways for the y, make deflection unheard of. Runs everything i put on the machine and wouldn't be surprised if it would do the one off mild steel part but i haven't and probably won't test that theroy. For the price this machine is at the top of the 3018 listing, and looks nice with included wire management, and very little calibration needed to get the machine to a repeatable cuts!

Trustpilot

1 month ago

3 weeks ago