Customer Services

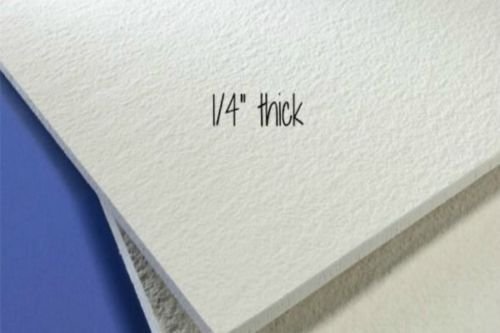

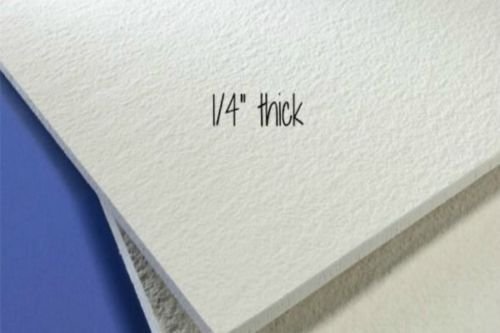

Fiberfrax is made of non-asbestos ceramic fibers, woven loosely together to form boards that withstand the high temperatures of fusing and the corrosive effects of molten glass. Just like fiber paper, glass can be placed directly onto the surface of the mold. It will leave a very subtle texture on the bottom side of the glass. For a very smooth surface, lightly sand the surface and edges of the mold before firing. Remember that anytime you are working with fiberboard you should wear a respirator. After your project is finished, it may pick up some fiber particles that can be cleaned off with water. Carve into it with woodworking tools to make a textured design that you cast or fuse into. Cut it with an X-acto knife to make a custom or irregular shaped drop out molds. FIBERFRAX BOARD is 1/4" thick. Sheet size is 12" x 12". Use as a lining to protect the expensive (and easily eaten away by molten glass) firebrick in your kiln. Use on your workbench as a heat proof pad to set your Rapid Fire Kiln or slumping molds on. HELPFUL HINT: When first fired, Fiberfrax® board will turn brown, as the sugar based binder burns off. Provide adequate ventilation for this initial prefire (~800°F). No shelf primer is needed when using Fiberfrax® board at temps up to ~1200°F. For single time use, fiberboard can be used as is. For multiple firings, treat first with mold hardener, pre fire to cure, and coat with kiln wash. Instructions included. THIS IS FIBERBOARD NOT FIBER PAPER!

Trustpilot

2 weeks ago

1 day ago