Klantenservice

Copyright © 2025 Desertcart Holdings Limited

🔧 Silence the squeak, not your style.

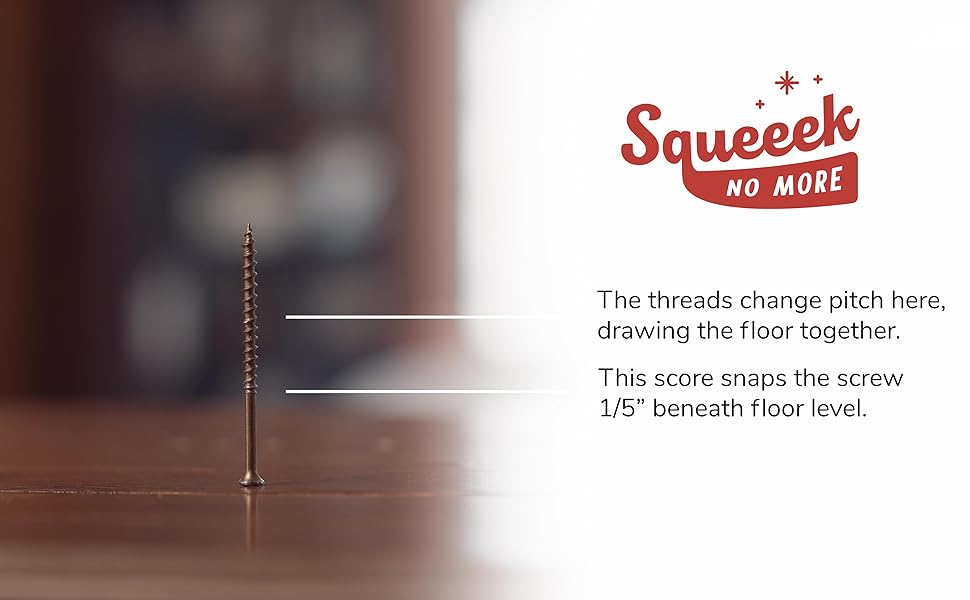

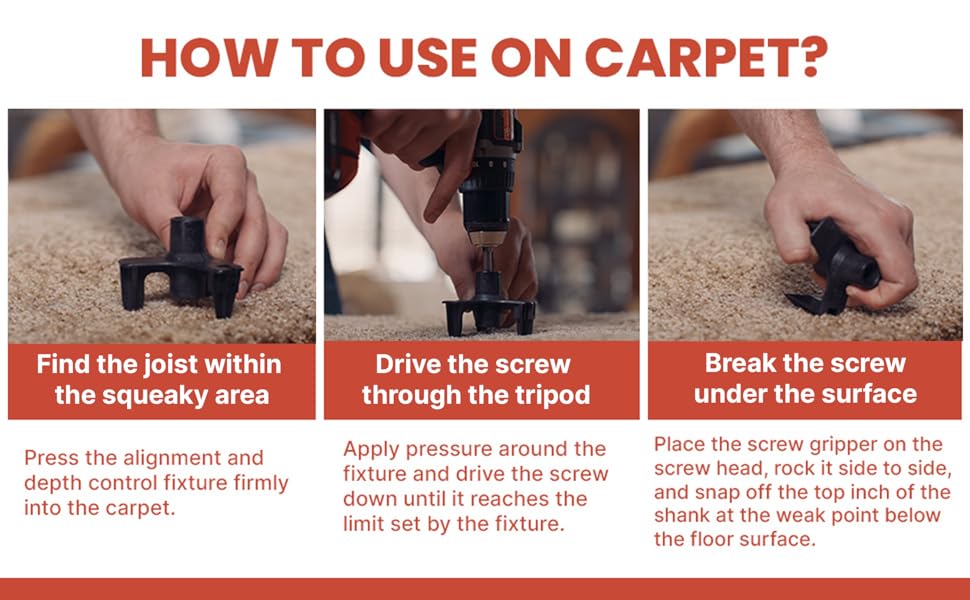

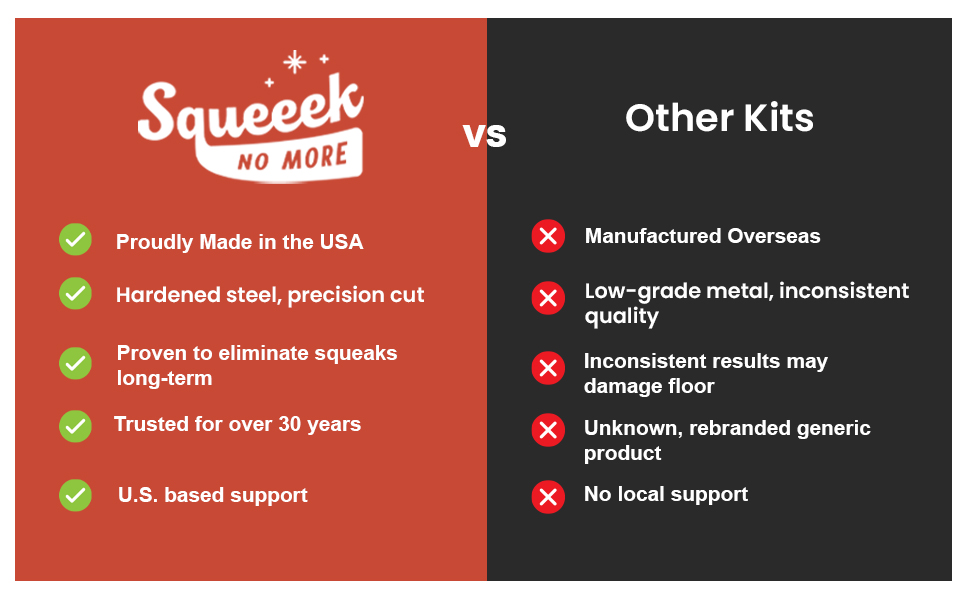

O'BERRY Enterprises 3251 Squeak Replacement Screws are precision-engineered, zinc-plated steel fasteners designed to work exclusively with the SQUEEEK NO MORE kit. Each screw snaps 1/4 inch below the floor surface for an invisible, damage-free repair on all floor types, making squeaky floors a thing of the past with professional-grade durability and ease.

| Material | Steel |

| Drive System | Double Square |

| Head Style | Square |

| Item Dimensions LxWxH | 7 x 3 x 1 inches |

| Exterior Finish | Coated |

| Thread Size | #00-90 |

| Metal Type | Stainless Steel |

| Brand | O'Berry Enterprises |

| Color | Yellow |

| Item Weight | 0.01 Ounces |

| Thread Coverage | Fully Threaded |

| Fastener Type | snap |

| Thread Style | Left Hand |

| Size | Pack of 1 |

| Manufacturer | Standard Plumbing Supply |

| Part Number | 3251 |

| Item Weight | 0.01 ounces |

| Product Dimensions | 7 x 3 x 1 inches |

| Item model number | 3251 |

| Is Discontinued By Manufacturer | No |

| Finish | Zinc Plated |

| Item Package Quantity | 1 |

| Measurement System | Imperial |

| Usage | Wood |

| Included Components | wood-screws |

| Batteries Included? | No |

| Batteries Required? | No |

| Warranty Description | Warranty |

Trustpilot

1 week geleden

1 dag geleden